.

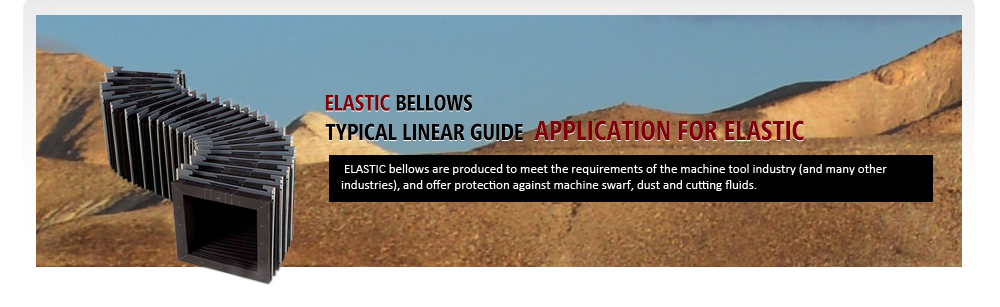

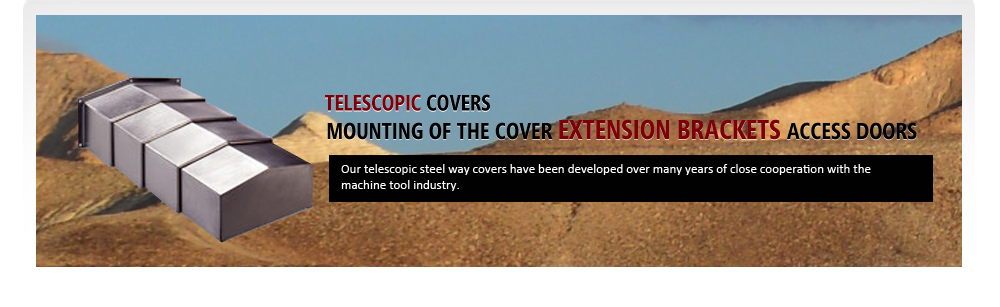

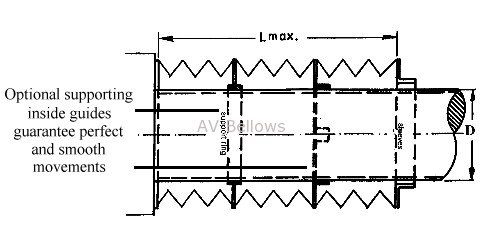

They are very popular in the measuring and medical industry and for spindles, columns and shafts. The Laminated Bellows are an inexpensive solution, their main advantage is the great variety in shapes, designs and colors. Folded construction, manufactured from a tough synthetic fabric and nylon laminate. Central support frames with nylon gliders or roller guides. Reinforcement by means of wire straps or plastic strips can be provided at the inside edges of the laminated Bellows where necessary. Extension stops are incorporated into the design depending on the application and requirements. These require a clear space of 20-30 mm (0.79 - 1.18 Inch) between the guideway and the inner faces of the bellow.

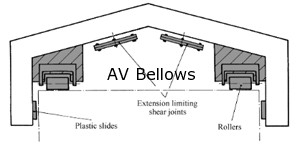

As all Laminated Bellows are manufactured to suit customers\` individual requirements, we would need details of any external influences, such as cutting fluid used, temperature range, mounting position and maximum traverse speed. All types of Laminated Bellows are produced of a multi layered material, a unique strong laminated/glued connection between inside and outside material. Central frames, for stiffening, are supported via plastic or brass gliders as well as rollers on the guide way and are limited at the sides.

As a general rule, plastic rollers are used for process speeds in excess of 20 metres/min. Metal mounting frames, snap fasteners or velcro tape can be supplied within the dimensions of the bellow to suit special applications.

For easy installation or replacement we have created special designs in laminated bellows that allow mounting the bellows afterwards. The bellows will then be delivered to you with all the necessary equipment to close and seal it. This is a simple, reliable and cost-efficient way to handle this type of problem. For heavy duty applications we have developed (based on intensive experience and experiments) a choice of mounting elements that can be offered as a reliable base for a perfect function of various covers. A combination of dividing and supporting frames of metal and plastic and/or with rollers or plastic gliders can be delivered as required

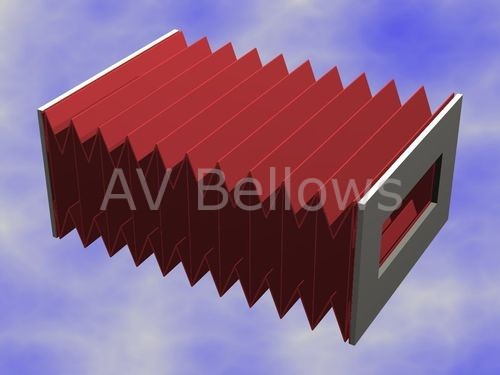

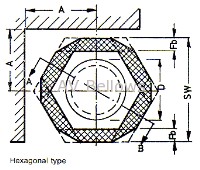

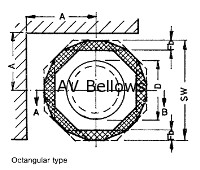

Polygonal laminated bellows are designed for horizontal and vertical applications. Excellent extension to compression ratios offer little resistance to machine capacity, and their clean lines and smart finish will compliment the appearance of your machine tools. Folded construction, manufactured from a tough synthetic fabric and nylon laminate. Built in steel mounting plates are provided for easy fitting of the cover to the machine. As an alternative we can offer snap fasteners or velcro tape to suit your special applications or requirements. For easy installation or replacement we have developed special designs that allow mounting or removing the bellow afterwards. The bellow will be delivered to you with all the necessary equipment (e.g. velcro tape) to close and seal it. This is a simple, reliable and cost-efficient way to handle this type of problem.

Design options (examples):

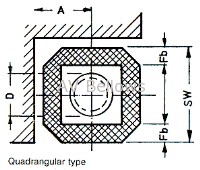

Cross-section of polygonal laminated bellow

| FB - Width of fold | A - Required space for the bellow | |

| SW - Width of the bellow | D - Diameter of the shaft, spindle, column | |

| Lmax - Maximal total extension | Lmin - Minimal total compression |

| FB in mm | FB in Inch | FAZ in mm | FAZ in Inch | FZd in mm | FZd in Inch |

| 7,5 | 0,30 | 10 | 0,39 | 3 | 0,12 |

| 10 | 0,39 | 13 | 0,51 | 3 | 0,12 |

| 12,5 | 0,49 | 18 | 0,71 | 3 | 0,12 |

| 15 | 0,59 | 20 | 0,79 | 3 | 0,12 |

| 17,5 | 0,69 | 25 | 0,98 | 3 | 0,12 |

| 20 | 0,79 | 28 | 1,10 | 3 | 0,12 |

| 22,5 | 0,89 | 30 | 1,18 | 3,5 | 0,14 |

| 25 | 0,98 | 35 | 1,38 | 3,5 | 0,14 |

| 30 | 1,18 | 40 | 1,57 | 3,5 | 0,14 |

| 35 | 1,38 | 48 | 1,89 | 4 | 0,16 |

| 40 | 1,57 | 55 | 2,17 | 4 | 0,16 |

| 50 | 1,97 | 65 | 2,56 | 4 | 0,16 |

| 60 | 2,36 | 80 | 3,15 | 5 | 0,20 |

Ph : 0422 2395831