Telescopic Covers

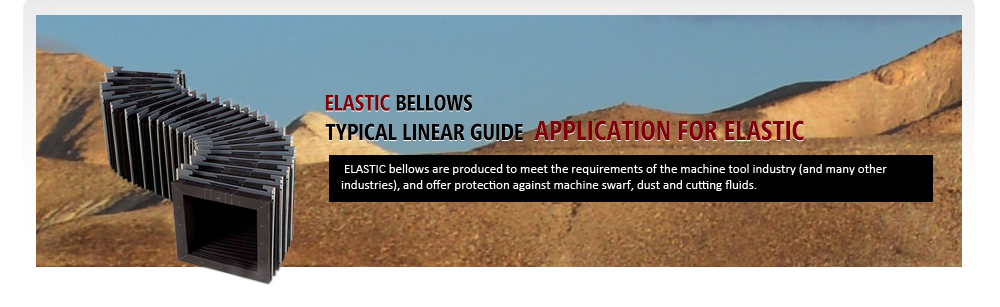

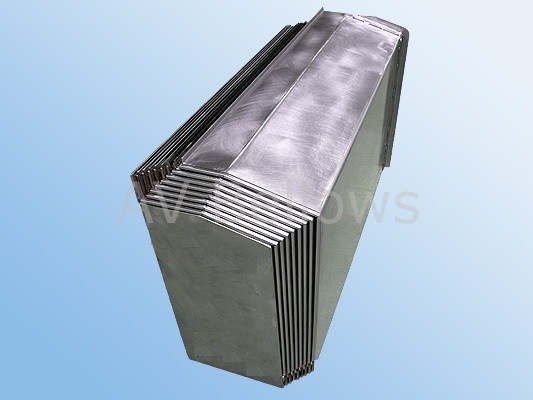

Our telescopic steel way covers have been developed over many years of close cooperation with the machine tool industry. The steel way covers will protect machine tool bed ways against damage by swarf and coolant. They reduce sideways wear, thus maintaining the accuracy of the machine and keeping maintenance cost to a minimum. We offer types that are best for easy replacement as well as ones for heavy duty operating conditions.Our telescopic covers are manufactured of best quality cold reduced mild steel sheet and are produced to a high degree of accuracy. They have a polished finish that will enhance the appearance of your machine. We also offer all types in stainless steel or with black anodized finish. Each box section of the cover is tightened against the adjoining one by a polyurethane wiper, which is protected from hot chips by a stainless steel outer case. You can choose from various solutions for the wiper system depending on your requirements.

![]()

![]()

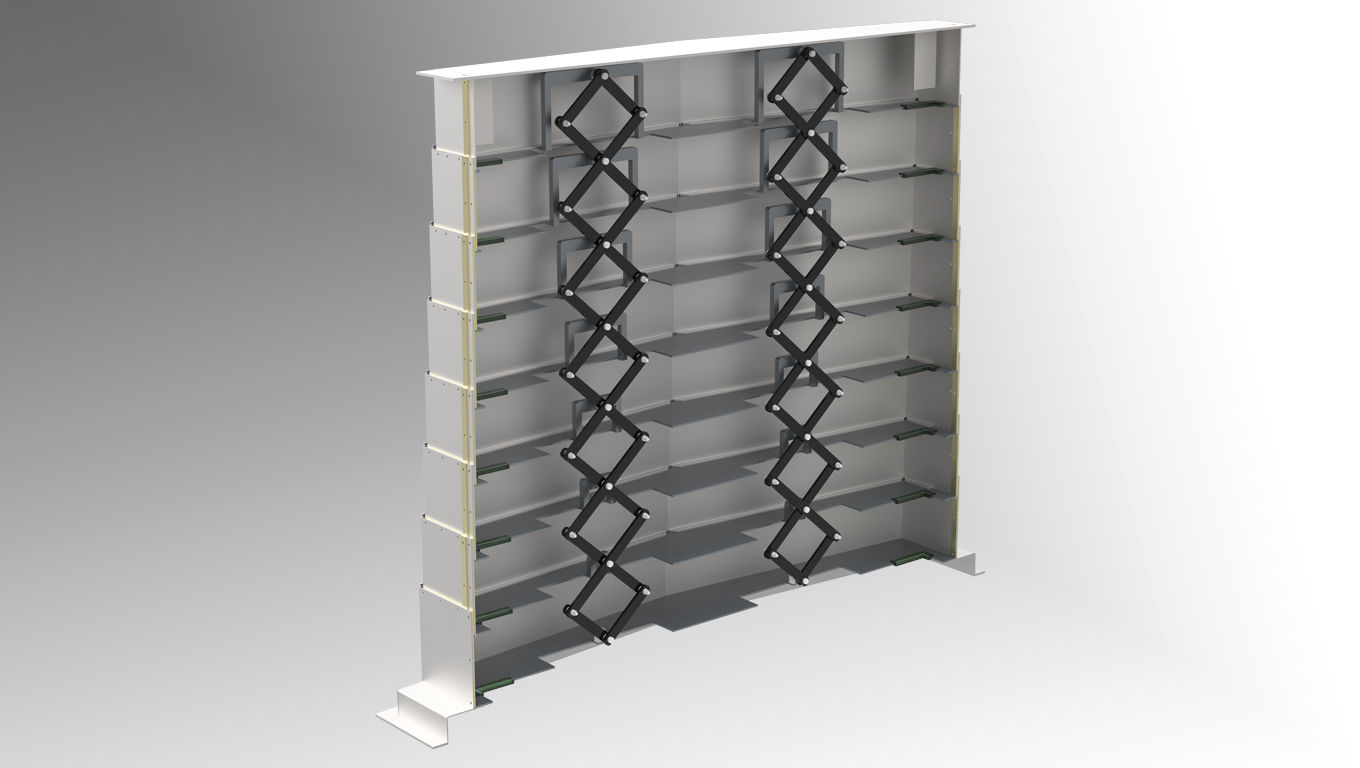

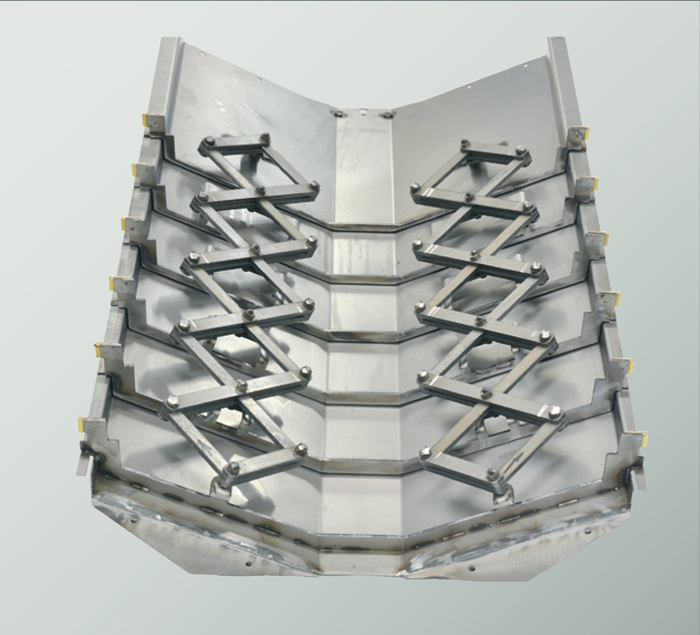

Cross-section of a telescopic covers

Smaller covers are fitted with low friction glide supports, heavier covers are supported on roller bearings. A non-slip chequer plate covering can be applied to the outer box in order to offer a platform for the operator to step on. The majority of machine tool slideways are exposed to abrasive particles as well as machine swarf. When these become lodged in the lubricating oil film, there is a real danger of pick-up and increase slideways wear, resulting in costly downtime. Therefore it is important to consider the steel covers at an early stage in the design of the machine. For this reason we provide a consultancy service to the machine tool manufacturer, and a technical representative will always be available to discuss and give advice on covers to suit the particular application. We even can offer support in the engineering process by designing your solution on our CAD-system (Autocad V 13.0, Genius).

Travel Speeds

For low speeds up to 10 meters (394 Inch) /minute: Standard cover designs apply using brass gliders with polyurethane inserts, brass side guides and bottom returns. If the side space is restricted, the bottom returns can be replaced by brass interlocks. For medium speeds of 10 (394) to 20 meters (787 Inch) /minute: Brass interlocks are not recommended. Rollers can be used to replace the gliders. For high speeds of 20 (787) to 30 meters (1181 Inch) /minute: Rollers are recommended on all applications and buffer blocks needed between the wiper and the catch strip. The buffers have the effect of decreasing the impact between adjacent covers and they also reduce the noise.

Configurations

The standard design is suitable for most applications. The slant top type is suitable for applications where coolant swarf are required to run off in one direction, when using the chevron type, coolant/swarf can run off in two directions and has increased strength for larger widths due to the apex fold. If your cover is over 1.5 meters / 60 Inch, the flat chevron type with two folds gives extra section strength. For vertical slideway applications, it is necessary to be able to support the telescopic covers on the back sides of the slideways. Therefore, removable slideway inserts should be positioned at the lower end of the column of each slideway, the length of which should be equal or greater than the closed length. At the top of the column, consideration should also be made for access so that covers can be inserted from above.

Additional features

Mounting of the cover

For the fixing of the covers you can also use external angle fixing, top, side or internal top mounting. It is possible to fasten the smallest section with an extended end plate. Where possible, it is recommended that this application should be avoided as swarf can accumulate between the covers and the extended end plate and so damage the wiper, reducing the effectiveness of the telescopic cover.

Walk-on

Where covers are positioned in areas of access to other parts of the machine, chequer plate can be fixed to the largest section only to allow the operator to stand/walk on the telescopic cover. Any other section should not be stood on.

Access doors

If it is necessary for maintenance purposes you can use access doors to access the slideways or ball screw without removing the complete telescopic cover assembly, an access doors can be fitted to the large section only.

Extension brackets

Where the closed length is in excess of the available free length of the slideway, it is necessary to support the telescopic cover using brackets as an extension to the slideways. Where the moving part finishes in close proximity to the end of the slideway, it is necessary to reproduce the cover guide faces of the slideways on the extension brackets to support the covers in their attitude.

Projecting Machine Parts

Where the telescopic covers are fastened to the moving parts, this part often carries slideway lubrication fittings, slideway wipers and positioning equipment. This effectively moves the largest section drive plate at its distance from the mounting face and consequently increases the length of the largest section. Parts projecting are above and between the machine slideways. Each drive plate has to be cut out to clear any projection within the internal envelope of the telescopic cover sections. It is necessary to indicate any projections.

Sealing of Telescopic covers

Due to the inherent design of telescopic covers, it is not possible to guarantee waterproof sealing. Standard designs will afford adequate protection. If additional protection is required, additional sealants can be applied to minimize the ingress of coolant. Long term sealing, however, is dependant on the end user providing constant care and maintenance of the cover surfaces and wipers. For trouble free operation wipers should wipe the full length of the operating surface. Side brackets, internal guiders and side guides should be checked for excessive wear. If necessary an additional bellow protection can solve this problem.

|

|

|

|

|

|

|

|

Ph : 0422 2395831